Our Sawmill

Get a Quote for Our Sawmill Services

Our Freeport, Michigan Lumber Mill

Buskirk Lumber has sawmills that service Michigan and Northern Indiana. Our main mill produces over ten million board feet of lumber annually and is one of the largest sawmills in Michigan!

Selling Timber Directly to the Mill

As a sawmill that buys timber, Buskirk Lumber has all of the resources that your project requires—including sawmills, logging crews, and our own fleet to transport your timber and lumber products. When you sell logs directly to our mill, you avoid outsourcing any work and additional associated fees including the trucking of your logs. And, when you have multiple jobs in one area, you save even more on equipment. See what factors influence the value of your timber.

As either primary or secondary end users of all products, we take extra care when working with your land and timber.

When dealing with brokers, consulting foresters, or loggers instead of selling directly to a mill, you get far less money for your timber. These third parties make money off of your timber either by reselling it to another sawmill or taking a percentage for their own commission.

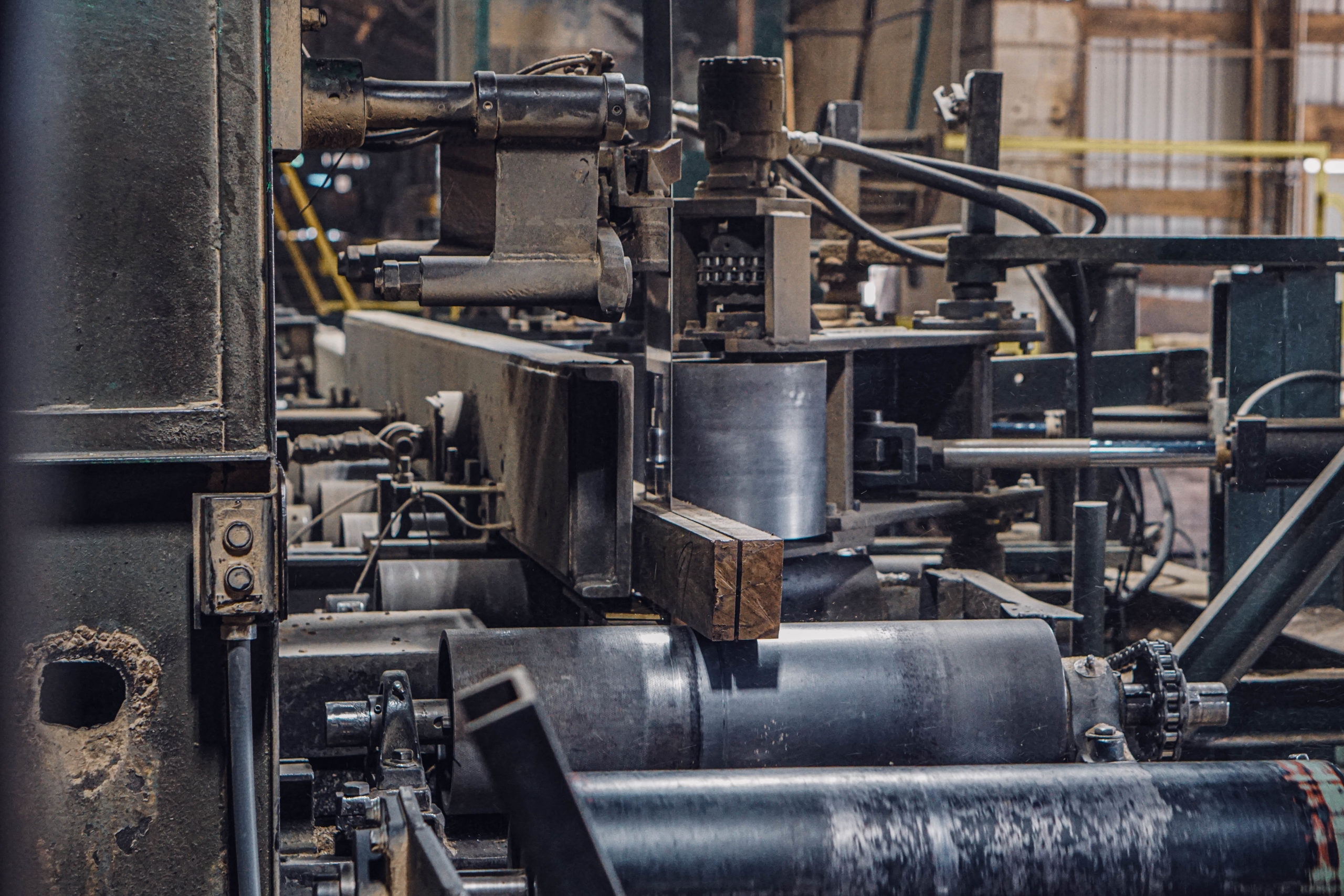

Step 1

Logs are stripped of their bark by using our ring debarker.

Step 2

Our Filer & Stowell Co. band head saws take off the edges of the logs — squaring them up and preparing them to be ripped into boards.

Step 3

The logs are then sent to our edger or resaw, at which time they are turned into boards. The lumber then gets trimmed to the desired width and length in the end trimmer.

Step 4

Double End Trimming.

End Products

Timber Harvesting is so much more than just cutting down trees. With the timber we purchase, we are able to create hundreds of finished end products to be put back into our communities.

Veneer

Logs

- Domestic and export

- High-end slicer and rotary logs

- Tabletops

Grade

Lumber

- FAS – 6-inches x 8-inches

- Select – 4-inches x 6-inches

- 1Com, 2a/2b, 3a/3b, and rustic

Specialty

Products

- Sea Wall Construction

- Trailer Decking

- Bridge Material

- Beams

Live Edge

Lumber

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Custom

Orders

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

By-Products

Sawdust is sold for animal bedding. The bark is sold as mulch and the material cut off from lumber is chipped and sold to wood pellet companies to be used as fuel.

Firewood

Logs

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

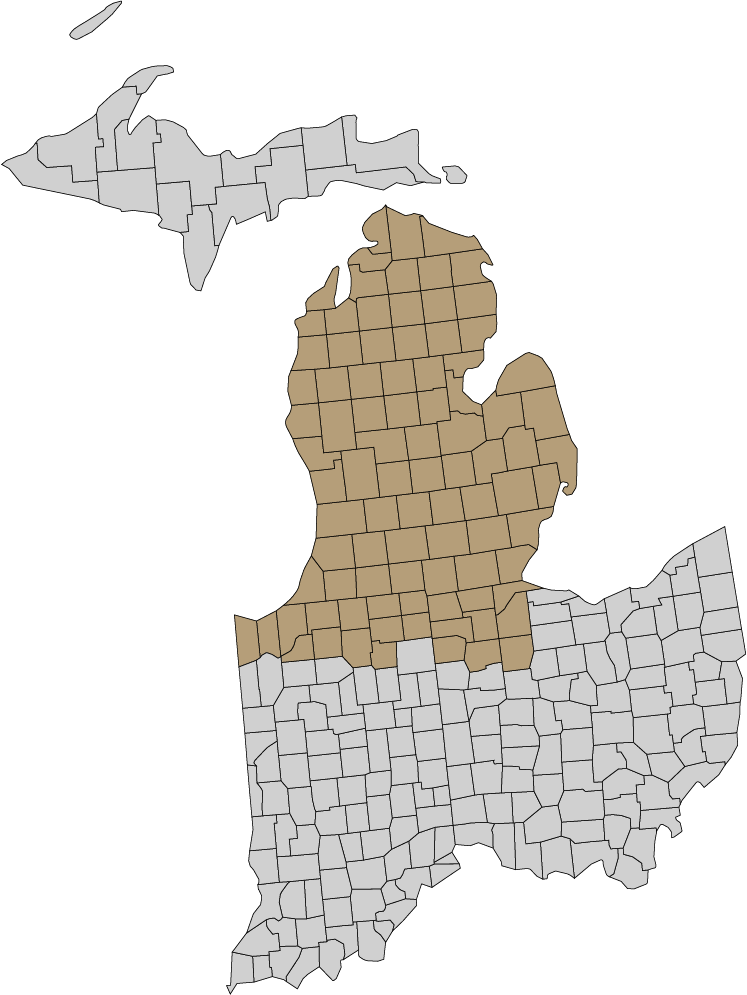

Sawmill Near Me

Our main lumber mill allows us to serve the following local communities in Michigan, Indiana, and Ohio.

Communities Served:

- Allendale, MI

- Benton Harbor, MI

- Big Rapids, MI

- Bowling Green, OH

- Cadillac, MI

- Cleveland, OH

- Elkhart, IN

- Elk Rapids, MI

- Gaylord, MI

- Grand Haven, MI

- Grand Rapids, MI

- Holland, MI

- Jenison, MI

- Kalamazoo, MI

- Manistee, MI

- Michigan City, IN

- Middlebury, IN

- Mt. Pleasant, MI

- Muskegon, MI

- Petoskey, MI

- Ravenna, MI

- Saint Johns, MI

- Sandusky, OH

- Saugatuck, MI

- Silver Lake, MI

- Toledo, OH

- Traverse City, MI

- West Olive, MI

We Buy Your Timber!

Ready to profit from your standing timber? Sell to our mill in Michigan! Get started today by giving us a call or sending us a note.